Metabo Welding Machine MIG/MAG 160 Specifications Page 16

- Page / 52

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

16

ENGLISH

Welding current (voltage)

The welding current (voltage) is set with

the welding step selector switch:

MIG/MAG 150/20 XT

− 6 steps

MIG/MAG 170/30 XTC (Combi)

12 steps

− 6 steps at 230 V

− 6 steps at 400 V

MIG/MAG 200/40 XT, MIG/MAG 250/60

XT, MIG/MAG 300/45 XT

12 steps

− 2 coarse steps

− 6 fine steps

6.3 Backburn Time

When correctly set the backburn time

prevents the electrode wire from sticking

to the weld pool. Setting is adjusted by

the backburn time potentiometer (48).

− Backburn time potentiometer knob

(48) turned fully to the

left = minimum backburn time.

− Backburn time potentiometer knob

(48) turned fully to the

right = maximum backburn time.

6.4 Gas-shielded Arc Weld-

ing

A

Caution!

Always check before starting work:

− Correct electrode wire installed?

− Correct shielding gas connected?

− Gun correctly equipped (liner,

spiral, tip/shroud and guide

tube)?

1. Attach earth cable at a suitable loca-

tion to the workpiece.

2. Open cylinder valve and set desired

gas flow rate.

Change gas shroud, if necessary.

Rule of thumb for calculating the

required amount of shielding gas

Amount of shielding gas [l/min] =

10 x wire diameter [mm]

Example:

Electrode wire diameter 1 mm

required amount of shielding gas 10 l/

min

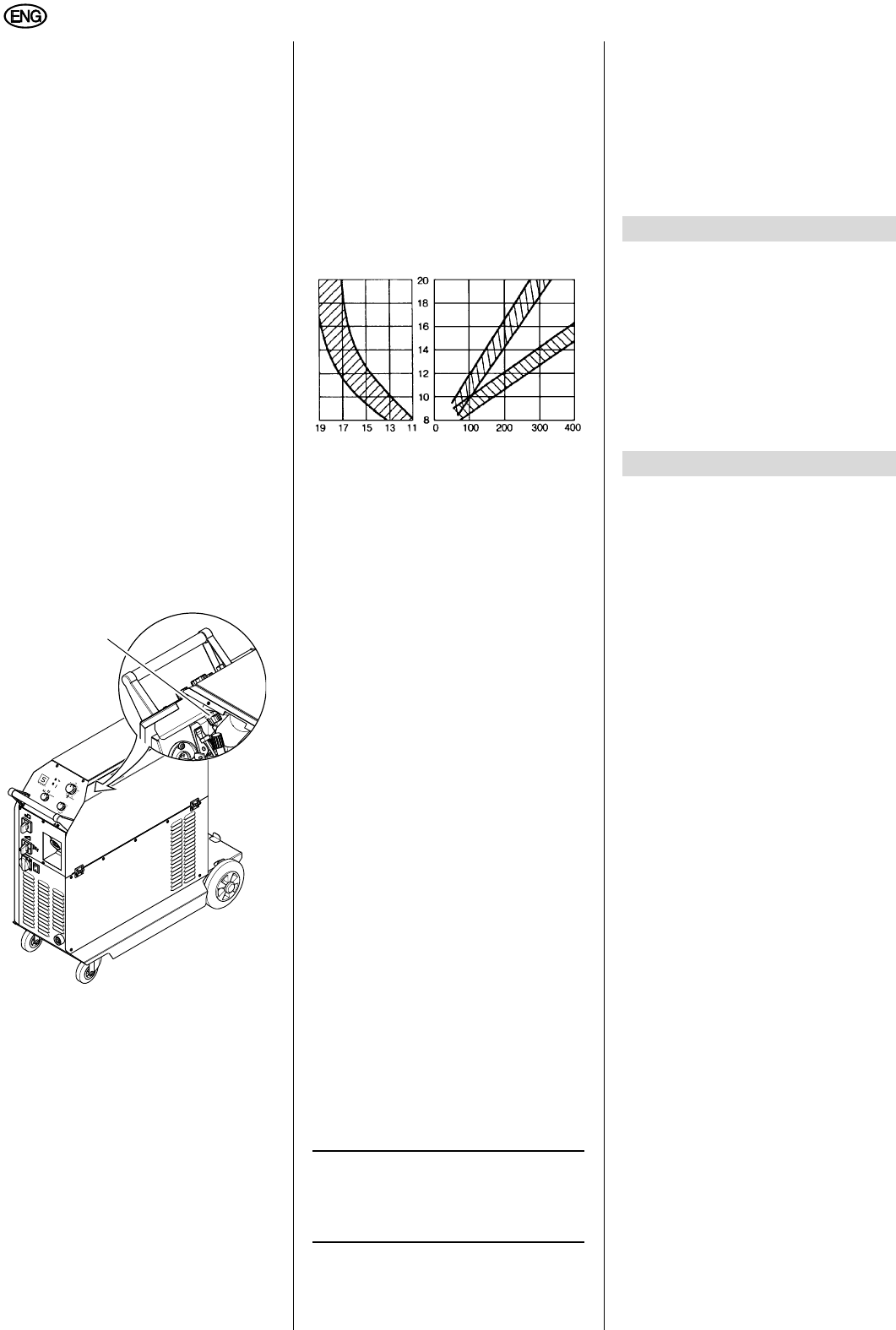

Diagram for the exact determination

of the shielding gas amount required

3. Set the welding current (voltage).

A

Caution!

Never actuate the welding current

(voltage) step switch during the run-

ning welding process.

Switching under load causes an over-

load and damages the switches.

4. Select desired operating mode.

5. Set the wire feed speed.

6. Turn machine on at the main switch.

The welding machine is now opera-

tional.

2-step mode (manual welding)

1. Press and hold trigger switch;

the welding process starts.

2. Release trigger switch;

the welding process ends.

4-step mode (continuous welding)

1. Press and release trigger switch;

the welding process starts.

2. Press and release trigger switch

again;

the welding process ends.

Spot weld mode

1. Set the weld time.

2. Press trigger switch;

the spot welding starts.

The welding process ends automati-

cally after the set weld time.

3

Note:

Releasing the trigger switch

before the set weld time is over also

ends the welding process.

6.5 Shutting Down

1. Close gas cylinder valve.

2. Turn machine OFF at the main

switch.

3. Disconnect earth cable from work-

piece.

4. Unplug power cable.

This welding machine contains no user-

serviceable parts.

Depending on dust build-up it should be

blown out every 4 to 6 months with dry

compressed air.

Periodically check the machine for visi-

ble defects.

Contact a qualified electrician if any of

the cables are damaged.

For these MIG/MAG welding machines

we recommend the following accesso-

ries. They have been tested with the

machines and ensure unproblematic

operation.

A Welding gun for 150/20 XT,

SB 14 (not detachable)

1) 3 m torch leads

B Welding gun for 170/30 XTC,

SB 15 KZ-2

1) 3 m torch leads

2) 4 m torch leads

3) 5 m torch leads

C Welding gun for 200/40 XT and

250/60 XT, SB 25 KZ-2

1) 3 m torch leads

2) 4 m torch leads

3) 5 m torch leads

D Welding gun for 300/45 XT,

SB 36 KZ-2

1) 3 m torch leads

2) 4 m torch leads

3) 5 m torch leads

E Earth cable for 150/20 XT

1) 3 m, 16 mm

2

(not detachable)

F Earth cable for 170/30 XTC,

200/40 XT and 250/60 XT

1) 3 m, 25 mm

2

G Earth cable for 300/45 XT

1) 5 m, 35 mm

2

H Dual clock pressure regulator

1) without stop valve

2) with stop valve

I Adaptor for electrode wire spools

1) 5 kg spools steel/stainless steel

and 2 kg aluminium spools

2) 15 kg basket coils steel/stain-

less steel and 7 kg aluminium

basket coils

J Welding visor

1) Automatic visor,

shade DIN 11

48

Amount of shielding gas in l/min Aluminium

Steel

Current in A

Gas shroud diameter

in mm

7. Maintenance

8. Available Accessories

- MIG MAG 150/20 XT 1

- MIG MAG 170/30 XTC 1

- MIG MAG 200/40 XT 1

- MIG MAG 250/60 XT 1

- MIG MAG 300/45 XT 1

- Schweißgerät MIG MAG 2

- 2.1 Bestimmungsgemäße 3

- Verwendung 3

- Inhaltsverzeichnis 3

- 1. Zuerst lesen! 3

- 2. Sicherheit 3

- 2.2 Symbole auf dem Gerät 4

- 3.1 Bedienteil 4

- 3. Bedienelemente 4

- (34) gegen Umfallen sichern 6

- 6. Bedienung 7

- Schutzgasmenge in l/min 8

- Aluminium Stahl 8

- Stromstärke in A 8

- Gasdüsendurchmesser 8

- 11.1 Allgemeine Störungen 9

- 8. Lieferbares Zubehör 9

- 9. Reparatur 9

- 10. Umweltschutz 9

- 11. Störungen 9

- 12. Technische Daten 10

- 2. Safety 11

- 2.1 Specified Conditions of 11

- Table of Contents 11

- 1. Please Read First! 11

- 2.2 Symbols Used 12

- 3.1 Control Panel 12

- 3.2 MIG/MAG 150/20 XT 12

- 3.3 MIG/MAG 170/30 XTC 12

- 3. Operating Elements 12

- 6.1 LED Indicators 15

- 6.2 Setting the Welding 15

- Parameters 15

- 6. Operation 15

- Current in A 16

- Gas shroud diameter 16

- 11.1 Trouble Shooting 17

- 9. Repairs 17

- 10. Environmental Protection 17

- 11. Faults 17

- 12. Technical Specifications 18

- FRANÇAIS 19

- NEDERLANDS 27

- Indice del contenido 35

- 2. Seguridad 35

- 2.1 Uso según su finalidad 36

- 2.2 Símbolos en la máquina 36

- 3.1 Elemento de mando 36

- 3. Elementos de mando 36

- 3.4 MIG/MAG 200/40 XT 37

- MIG/MAG 250/60 XT y 37

- MIG/MAG 300/45 XT 37

- 4. Transporte 37

- 5.4 Introducción del alambre 39

- 11.1 Averías generales 42

- 11. Averías 42

- 12. Especificaciones técnicas 42

- 2.1 Korrekt anvendelse 44

- Indholdsfortegnelse 44

- 1. Læses først! 44

- 2. Sikkerhed 44

- 2.2 Symboler på apparatet 45

- 3.1 Betjeningsdel 45

- 3. Betjeningselementer 45

- MIG/MAG 250/60 XT og 46

- 4.1 Krantransport 46

- 4. Transport 46

- 5.1 Tilslut gasflasken 47

- 5.2 Strømtilslutning 47

- 5.3 Sæt svejsetrådrullen i 47

- 5.4 Før svejsetråden ind 47

- 5. Driftsforberedelse 47

- 6. Betjening 48

- Beskyttelsesgasmængde i l/min 49

- Aluminium Stål 49

- Strømstyrke i A 49

- Gasdysediameter 49

- 11.1 Generelle forstyrrelser 50

- 9. Reparation 50

- 10. Miljøbeskyttelse 50

- 11. Forstyrrelser 50

- 12. Tekniske Data 51

(52 pages)

(52 pages) (36 pages)

(36 pages) (17 pages)

(17 pages)

Comments to this Manuals