Metabo Spindle Moulder TF 100 M Operations Instructions Page 4

- Page / 44

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

7 Commissioning

7.1 1-Phase Power Supply

This machine must be connected to an earthed outlet and operated on a residual current device (RCD) of 30 mA

capacity. Supply voltage required 230V ±5% 50 Hz. Protect circuit with a fuse 16 A time-lag. A supply line lead

cross section of min. 3 x 2.5 mm

2

is required.

7.8 Dust Collector Automatic Start

The electrical installation must provide for automatic starting of the dust collector when the spindle moulder is

switched on, and for a 20 second switch-off delay after the spindle moulder is switched off.

7.7 Dust Collection

This spindle moulder must be connected to a dust collector.

- The fine dust of beech or oak is classified as cancer-causing.

The dust collector this spindle moulder is to be connected to must provide for a minimum air flow rate of

16 m/sec at the machine's dust extraction outlet.

The dust extraction outlet's nominal diameter is 100 mm.

7.6 No-Voltage Release

The switch is equipped with a no-volt release solenoid (magnetic switch) to prevent start-up after a power failure.

It the machine is not connected to the power supply the switch does not engage. In the event of a power failure

the machine has to be restarted by switching ON again.

7.5 Overload Protection

In case of an overload the build-in motor protection relay switches the power off. Let motor cool off for approx.

10 minutes before starting again.

7.2 3-Phase Power Supply

A 5-wire (L1-L2-L3-N-Earth) supply system is required. Connect with the 16A CEE industrial type plug to an

earthed outlet equipped with a residual current device (RCD) of 30 mA capacity. Supply voltage required 400V

±5% 50 Hz. Protect circuit with 3 fuses 16 A time-lag. A supply line lead cross section of min. 5 x 1.5 mm

2

is

required.

7.3 Direction Of Rotation

For machines with single-phase motor the direction of rotation is factory set. On machines with a three-phase

motor the direction of rotation must be checked after connection to the power supply. Start motor briefly. The

spindle, when viewed from the top, must turn counter-clockwise. To change the direction of rotation interchange

2 of the current conduction leads (black and/or brown). Do not connect the yellow-green earth lead to any of

the current conducting leads.

Note:

With a wrong direction of rotation there is danger of accident. Check direction of rotation carefully.

Have phases interchanged only by a qualified electrician!

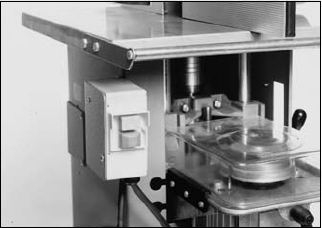

7.4 Switch

This spindle moulder is started by actuating the green push-button and

stopped by actuating the red button.

- TF 100 M 1

- 2 User Responsibility 2

- 3 Standard Accessories 3

- 6 Installation 3

- 5 Final Assembly 3

- 4 Optional Accessories 3

- 8 Safety Information 5

- 12 Jigs And Push Blocks 5

- 10 Scope Of Application 5

- 9 Workpiece Dimensions 5

- 13.2 Mounting A Tool 6

- 13 Controls 6

- 13.1 Definitions 6

- 13.4 Tool Height Setting 7

- 14.5 Making Tenons 9

- 14.5 Set-In Work 9

- 15 Care And Maintenance 9

- Wiring Instructions 10

- Table des matières 11

- 6 Mise en place 12

- 5 Montage initial 12

- 4 Accessoires en option 12

- 3 Matériel livré: 12

- 8 Consignes de sécurité 14

- 12 Accessoires d'amenée 14

- 13 Eléments de réglage 15

- 13.1 Définition des termes 15

- 14.5 Fraisage de tenons 18

- 15 Entretien et maintenance 18

- 2 Produktansvar/garanti 19

- Contents 19

- 3 Leveringsomfang: 20

- 5 Første gangs montering 20

- 4 Ekstrautstyr 20

- 6 Installasjon 20

- ≤øydimensjoner/skærehastighet 22

- 13 Betjeningselementer 23

- 13.1 Definisjoner av uttrykk 23

- 14.5 Fresing av tapper 26

- 15 Stell og vedlikehold 26

- Sisällysluettelo 27

- 2 Tuotevastuu / takuu 27

- 1 Tekniset tiedot 27

- 3 Toimituksen laajuus 28

- 4 Erikoistarvikkeet 28

- 6 Pystytys 28

- 5 Ensimmäinen asennus 28

- 12 Syöttöapulaitteet 30

- 8 Turvallisuusohjeet 30

- 9 Työstökappaleiden mitat 30

- 13.2 Jyrsimen kiinnitys 31

- 13 Ohjauselimet 31

- 13.1 Määritelmät 31

- 13.4 Jyrsinten korkeusasetus 32

- 14.5 Tappien jyrsintä 34

- 15 Hoito ja huolto 34

- 14.6 Panostusjyrsintätyöt 34

- Innehållsförteckning 35

- 6 Uppställning 36

- 5 Första montering 36

- 4 Extra tillbehör 36

- 3 Everansomfång 36

- 8 Säkkerhetsanvisningar 38

- 10 Användningsområde/-ändamål 38

- 12 Matarhjälpmedel 38

- 9 Arbetsstyckets dimensioner 38

- 13 Manöverelement 39

- 13.1 Begreppsförklaringar 39

- 14.5 Fräsning av tappar 43

- 15 Service och underhåll 43

- 14.6 Insatsfräsarbeten 43

(4 pages)

(4 pages)

(100 pages)

(100 pages)

Comments to this Manuals