Metabo PK 300 Operations Instructions Page 7

- Page / 19

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

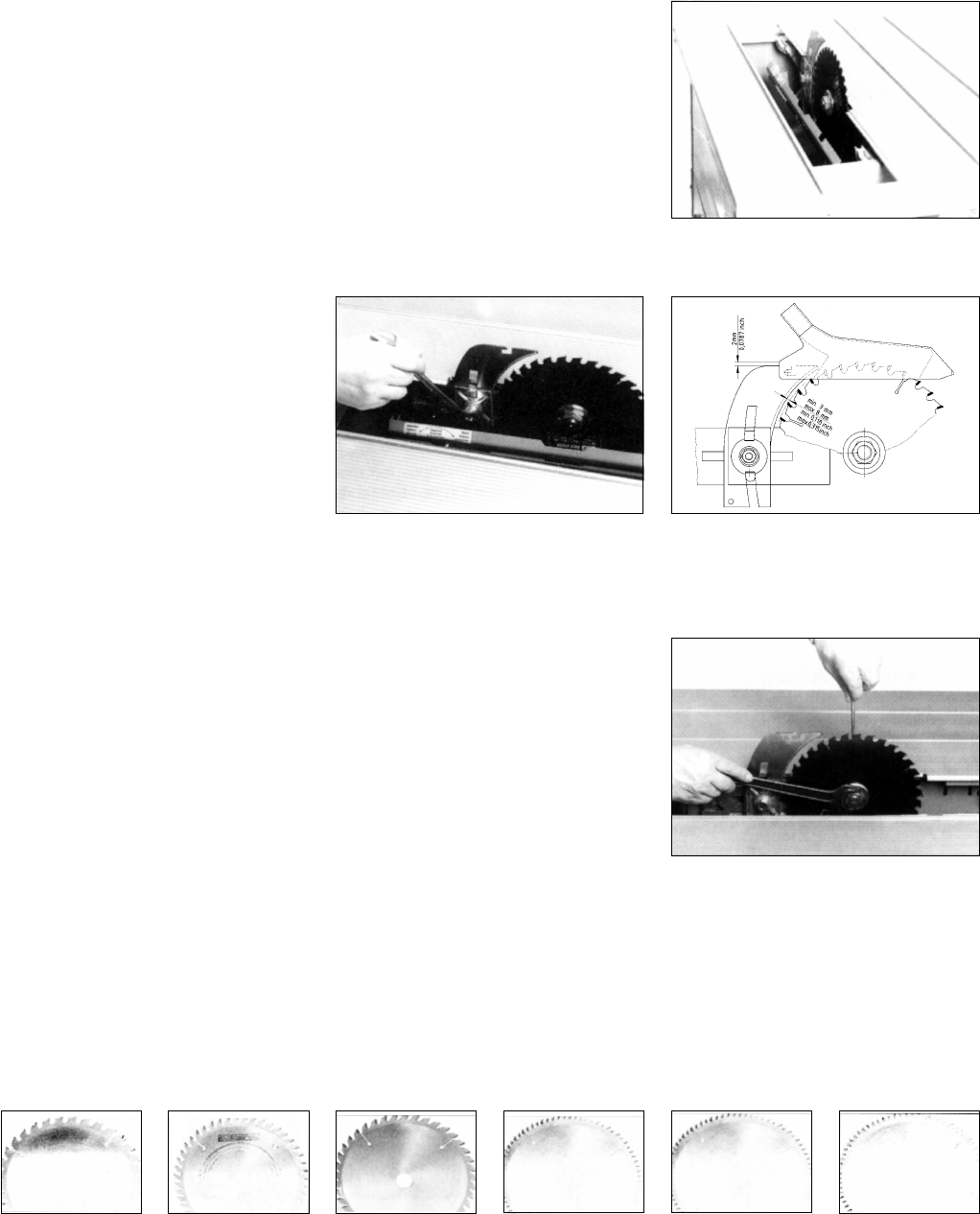

TCT blade T = 96 TF

Ø 300x3.2/2.6x30 mm

Trapezium-flat teeth.

For solid timber, ply,

plastic and aluminium

extrusions, fine

furniture boards.

Stock-no.

091 001 4145

TCT blade T = 96 VW

Ø 300x3.2/2.2x30 mm

Multiple alternating

teeth. For the ultimate

performance in cabinet

making. Cuts solid

timber as well as all

plywoods and boards.

Stock-no.

091 001 4137

TCT blade T = 72 KW

Ø 300x3.2/2.2x30 mm

Combination alter-

nating teeth.

Cuts Melamin boards,

extrusions, all kinds of

plastics.

Stock-no.

091 001 4129

TCT blade T = 60 DH

Ø 300x3.2/2.2x30mm

Pointed-hollow teeth.

For cutting plastic

laminated boards.

Makes scribing/scoring

blade obsolete.

Stock-no.

091 001 4102

TCT blade T = 48 UW

Ø 300x3.2/2.2x30 mm

Universal alternating

teeth.

For cutting cabinet

boards, veneered and

laminated boards as

well as solid timber.

Stock-no.

091 001 4110

TCT blade T = 28 W

Ø 300x2,6/1.8x30 mm

Alternating teeth.

General purpose blade

for rip and cross cuts,

timber and particle

board.

Standard delivery.

Stock-no.

091 001 4099

20

6 Saw Blades

Never use HSS blades, as these are not flexible enough and will crack or break easily.

Saw blades must be marked with the name or trade mark of the manufacturer. On this saw the following blades can be used

with the standard riving knife: min. Ø 250 mm, max. Ø 300 mm, arbor bore 30 mm, blade thickness/tooth width 1.8 - 2.5 mm.

Use of thinner or thicker blades requires a different riving knife.

The riving knife must not be wider than the width of the kerf and not narrower than the blade body.

5.6 Changing the Main Blade

Disconnect from power before servicing!

Insert lock bar from tool set through the hole in the table into the hole of the blade

flange below. Turn blade by hand to line up holes. Use 30 mm spanner from tool

set to loosen arbor nut.

Note: Left-hand thread, turn clockwise to loosen!

Take off arbor nut and blade. Before fitting another blade be sure that blade seat

and arbor thread are clean. Wipe of with rag any chips or saw dust which may

have deposited there, so blade can fit snug against flanges to ensure safe

operation. Fit blade so that teeth on top point towards the operator in front of saw.

Replace arbor nut and tighten. Do not overtighten.

Remove lock bar, close chip case and put removable table section back in place.

Install saw blade guard before starting the saw.

5.5 Setting of Riving Knife

Disconnect from power before servicing!

Set the height so that the top of the riving knife is not less then 2 mm below the crown of the saw blade.

Important! Check mounting screw regularly for stripped threads.

Lift chip case cover on both ends, pull forward by approx. 50 mm, then lower.

Riving knife and saw blade are now accessible for maintenance and servicing

The riving knife prevents the work

from closing behind the blade, thus

stalling it and causing kickback.

Except for set-in work (see para-

graph 11.3) never perform any

cutting operation without the riv-

ing knife in place and correctly

set.

Set riving knife to a distance of 3 -

8 mm against the saw blade.

- PK 300 K 1

- Scope of Application 3

- Table of Contents 3

- Product Liability/Warranty 3

- User Responsibility 3

- 2 Standard Delivery 4

- 3 Installation 4

- 4 Connection to Power Mains 5

- 6 Saw Blades 7

- 5.6 Changing the Main Blade 7

- 5.5 Setting of Riving Knife 7

- 7.1 Optional Accessories 8

- 8 Jigs and Push Blocks 8

- 9 Safety Rules 8

- 9.1 Problems 9

- 10 Dust Collection 9

- 11 Operation 9

- 11.1 Through Sawing 9

- 11.2 Rabetting and Grooving 10

- 11.6 Tenons and Slots 11

- 11.8 Cutting Wedges 11

- 14.1 Tool Maintenance 12

- 14 Care and Maintenance 12

- 13 Belt Tension 12

- 15 Wiring Diagram 13

- 16 Optional Accessories 13

- 17 Spare Parts List PK 300 K 14

- Wiring Instructions 16

- EB_Adr1B.fm 19

(14 pages)

(14 pages)

(108 pages)

(108 pages)

Comments to this Manuals